Support

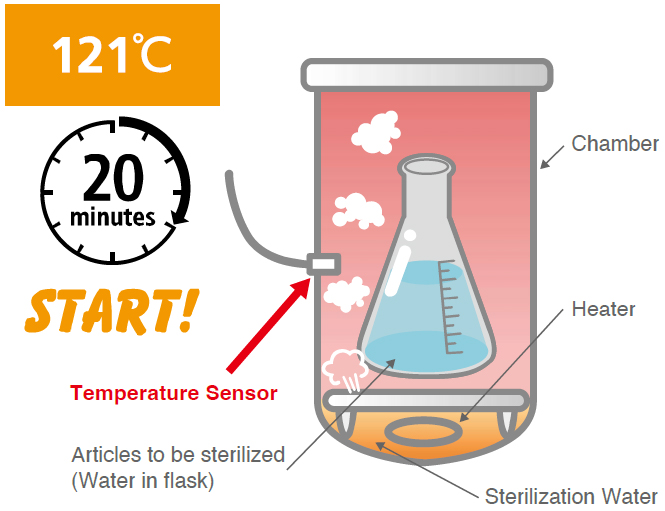

When the autoclave is started, the heater heats the sterilization water, and the temperature inside the chamber rises due to the steam generated. The temperature sensor on the chamber wall detects the ambient temperature of the temperature sensor, which is shown on the control panel display during operation (hereafter “chamber temperature”). After the chamber temperature reaches the set temperature, the sterilization process starts.

The articles to be sterilized are also heated by the steam generated inside the chamber and their temperature rises. The rate of temperature rise varies depending on the quantity, material, shape and accommodation way of the articles to be sterilized. In the sample case shown in the above figure, the more water there is, the longer it takes for the temperature to rise.

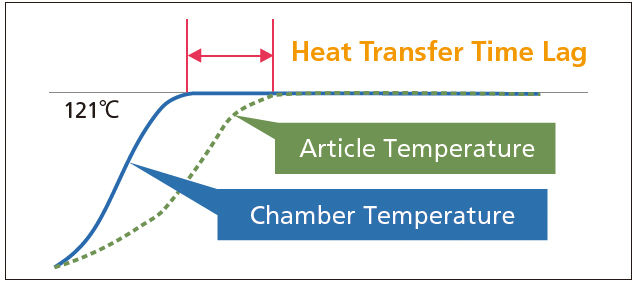

At this point, the chamber temperature has reached the set temperature, however the articles to be sterilized may not have reached the set temperature.

This is called “Heat Transfer Time Lag”.

Even if the articles to be sterilized have not reached the set temperature, the sterilization process may start when the chamber temperature reaches the set temperature. This may result in insufficient sterilization and BI test failure. For secure sterilization, it is recommended to add the Heat Transfer Time Lag to the sterilization time.

For details on “Heat Transfer Time Lag” and reference times, check below.

Heat Transfer Time Lag

FLS-1000 >

SX-700 / 500 / 300, SX-700E / 500E / 300E >

For measures of “Heat Transfer Time Lag” for secure sterilization, check below.

External Temperature Sensor

FLS-1000 >

SX-700 / 500 / 300, SX-700E / 500E / 300E >